BUILTnotBOT

Well-Known Member

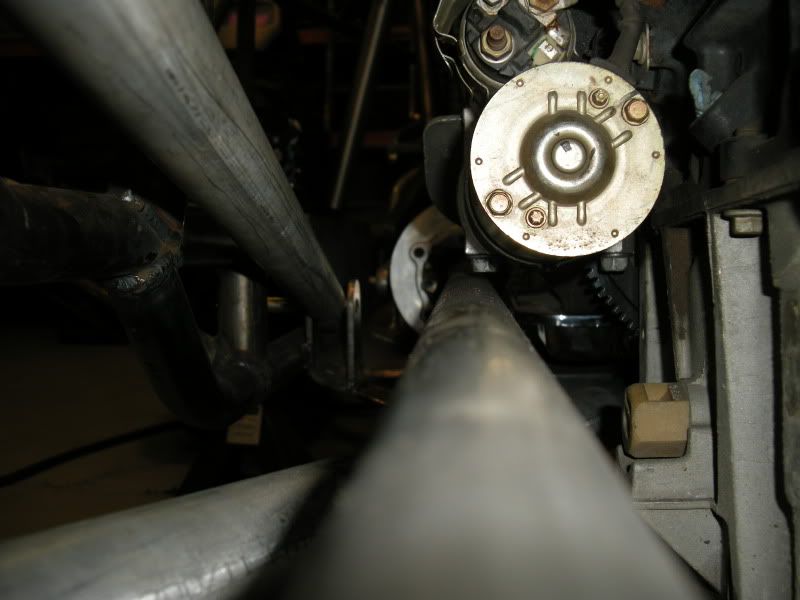

My 2 piece front vibrates like a SOB anything past 30mph in 4wd. Rear 2wd, front drive in neutral, with front hubs locked I don't even notice it. It's the angles i'm working with for the flipped 300 to clear my clutch fork on the 4 speed.

I've debated doing the 1350 axle shaft lately as well. But isn't there still vibes with that at speed? It's an axle shaft not a driveshaft...

My front 2 piece is a 14 bolt pinion with the gear cut off and pressed onto the pillow block. Was an easy choice with a diameter of 1-3/4" no problem finding tube or weld yokes.

I've debated doing the 1350 axle shaft lately as well. But isn't there still vibes with that at speed? It's an axle shaft not a driveshaft...

My front 2 piece is a 14 bolt pinion with the gear cut off and pressed onto the pillow block. Was an easy choice with a diameter of 1-3/4" no problem finding tube or weld yokes.

Last edited:

![IMG_2151[1].jpg](http://attachments.www.hardlinecrawlers.com/xfmg/thumbnail/33/33600-e84fbedae6fc3751054f9608521169da.jpg?1683575081)