Bringing this thread back from the dead. I had kinda forgotten about it. Been working on this one a little bit between time on the single seater trying to get it ready for a Harlan run in a couple weeks.

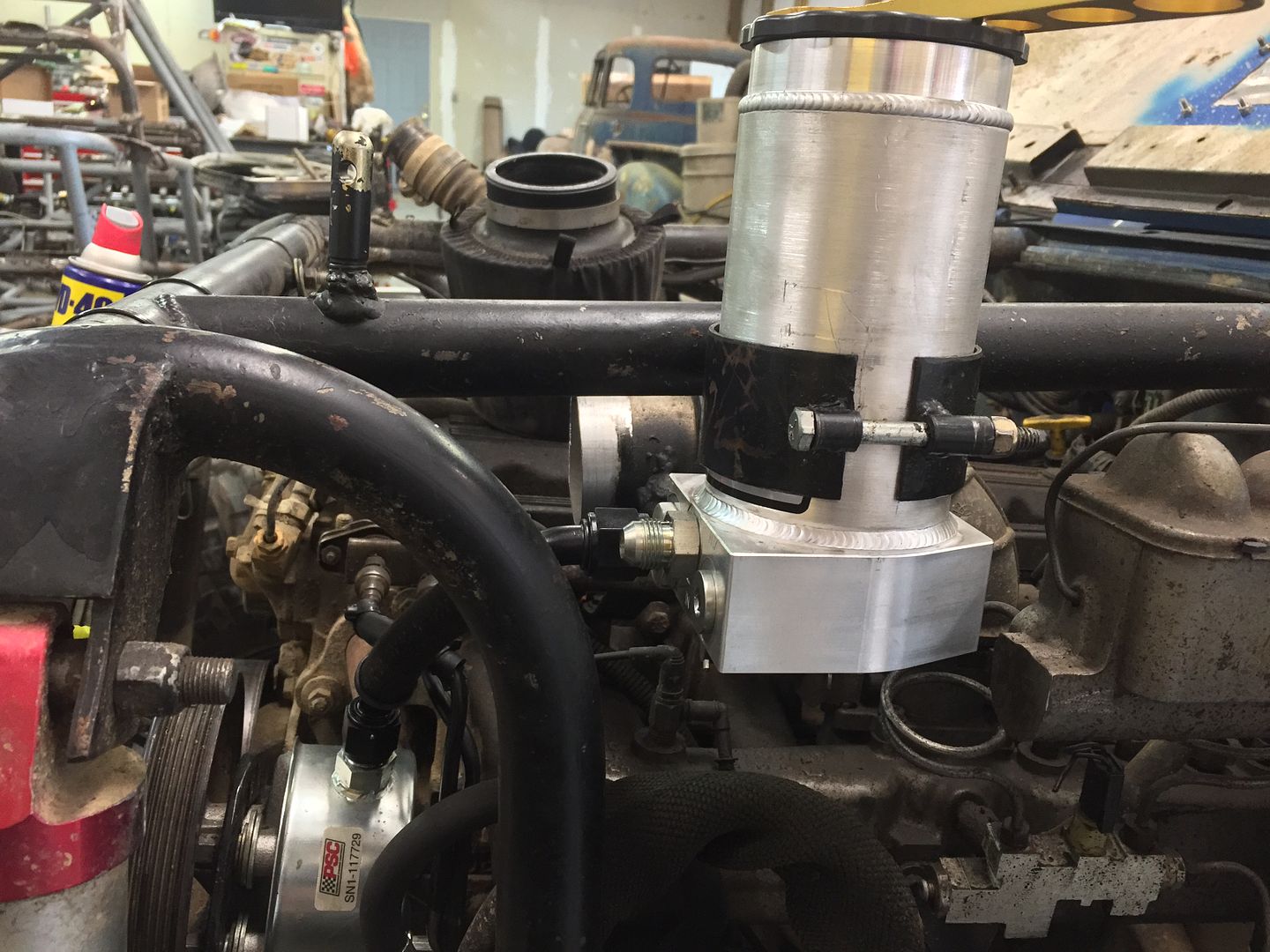

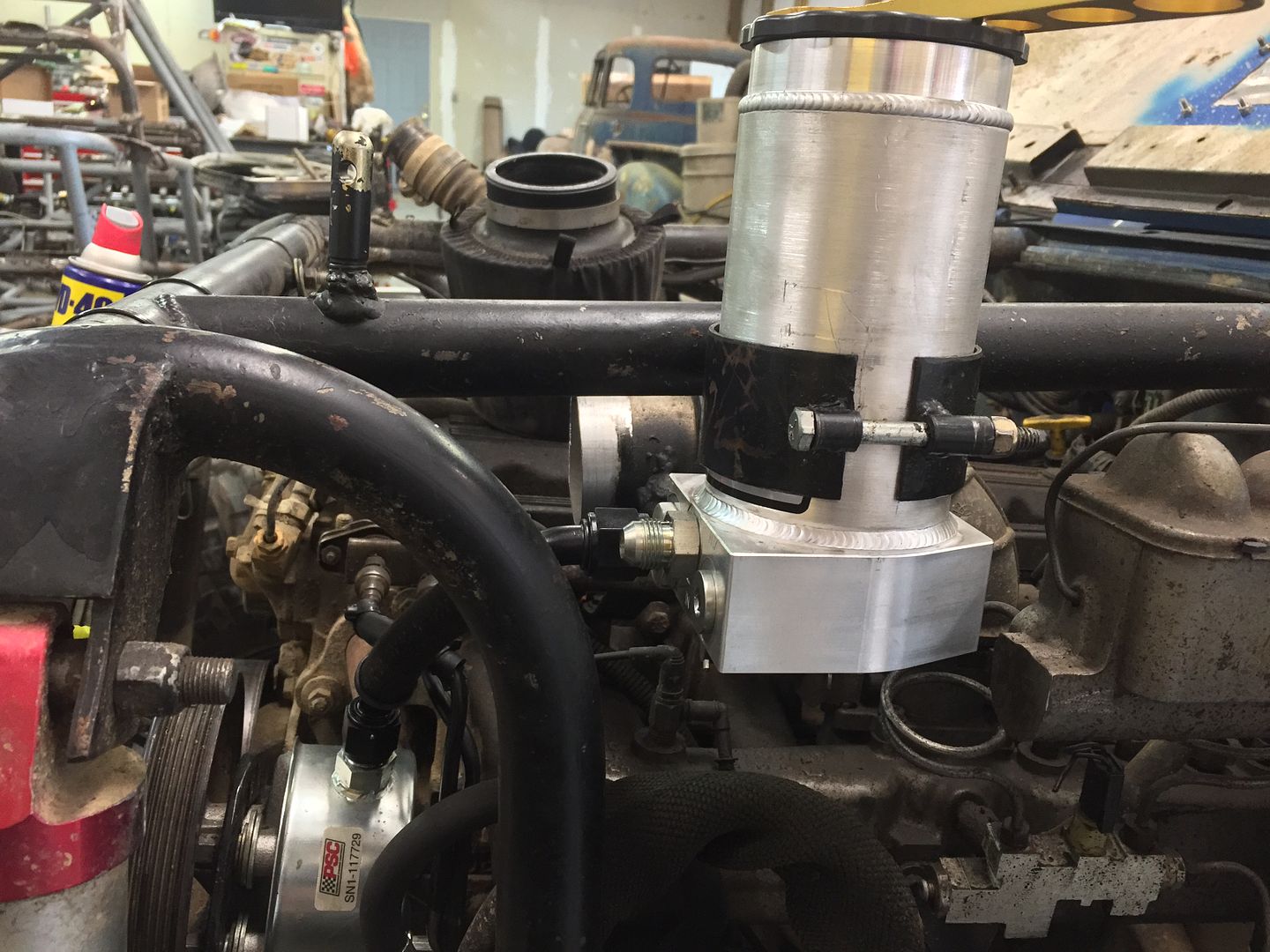

Several months back I put on a new PSC P pump, with the new generation PSC reservoir. And added a 16 pass -8 Derale cooler with fan mounted under the driver's seat. I think the old style reservoir was causing cavitation in the pump, which causes more heat than my cooler could handle, and burnt the pump up. It was a squealing machine, and would barely steer anymore with any resistance at all. I'm hoping this will solve the issues. I haven't had it out yet, but on the runs I made up and down my road it seemed to do a lot better. Only time will tell.

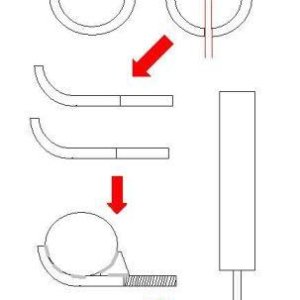

I've also been gathering the parts to upgrade the Dana 300 in this thing too. It was just struggling with the stock gears trying to turn 40s. A few months back I found a good deal on a set of front and rear 32 spline outputs. Monday I picked up another complete 300 that already had 4:1 gears in it but a broken stock rear output for a smoking deal. I tore it down, and gave it a good cleaning. I have the 32 spline rear output and front input installed already. I would have the whole thing back together already but I had to order some shift fork inserts because two were missing. As soon as they get here I'll finish putting it together. When it's all said and done I'll only have about $900 in a 4:1 300 with 32 spline f/r outputs. That's not too bad. It will definitely help this thing out a ton!

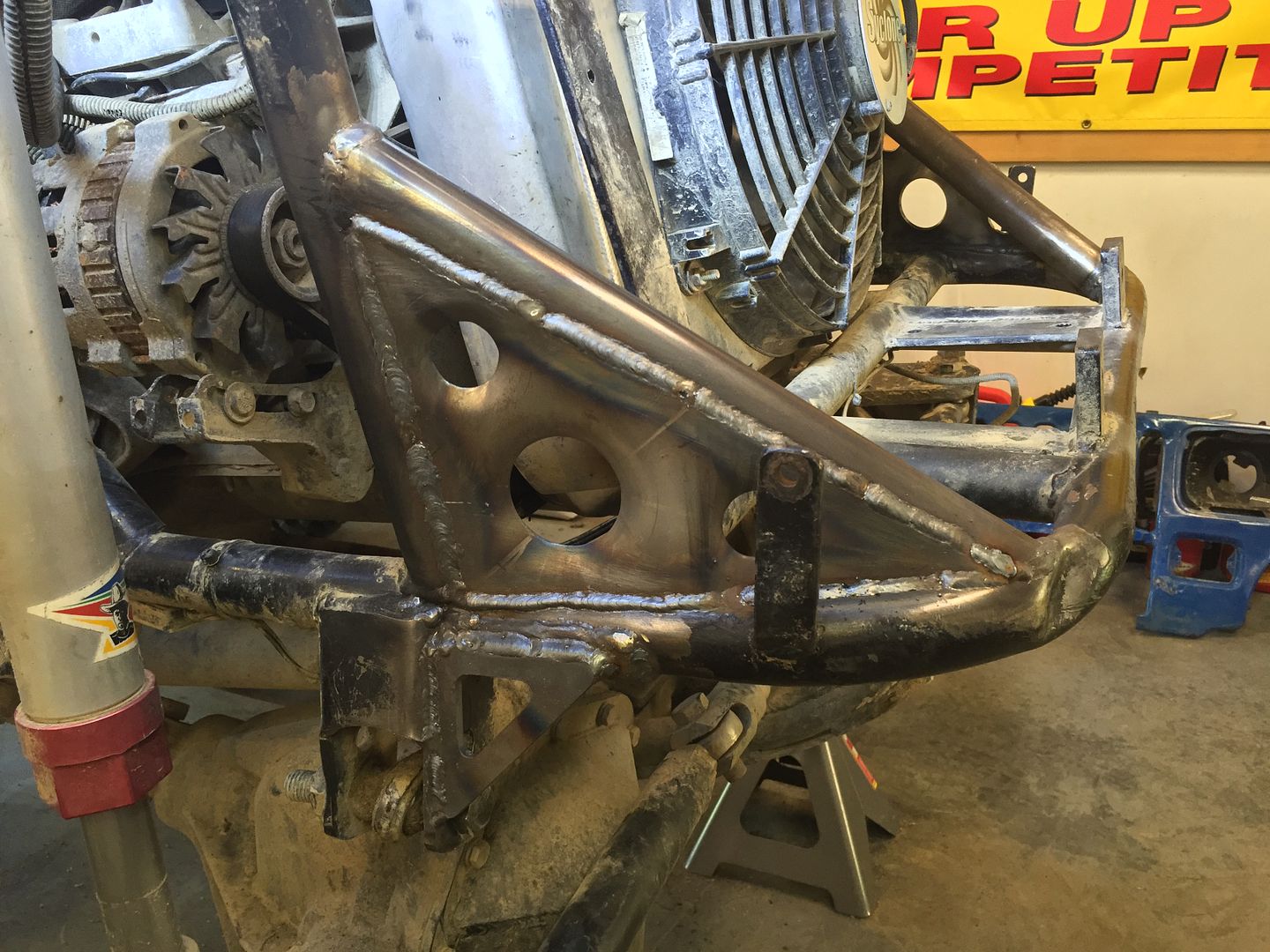

What 4:1 gears and 39" Reds do to stock output shafts.

A Dana 300 in 300 pieces.

This morning I dropped the skidplates, pulled the driveshafts, and pulled the stock 300 out. There's nothing wrong with it, just going to keep it around as a spare.

You may notice the Treps set on dig mode. They say you're supposed to air down for rockcrawling, right? That's the next project after I get the new case in. 3 of the 4 Stazworks wheels are leaking around the beads. I'm going to break them back down and try some bead sealer on them and hope it solves the problem.