Nuzzy

Well-Known Member

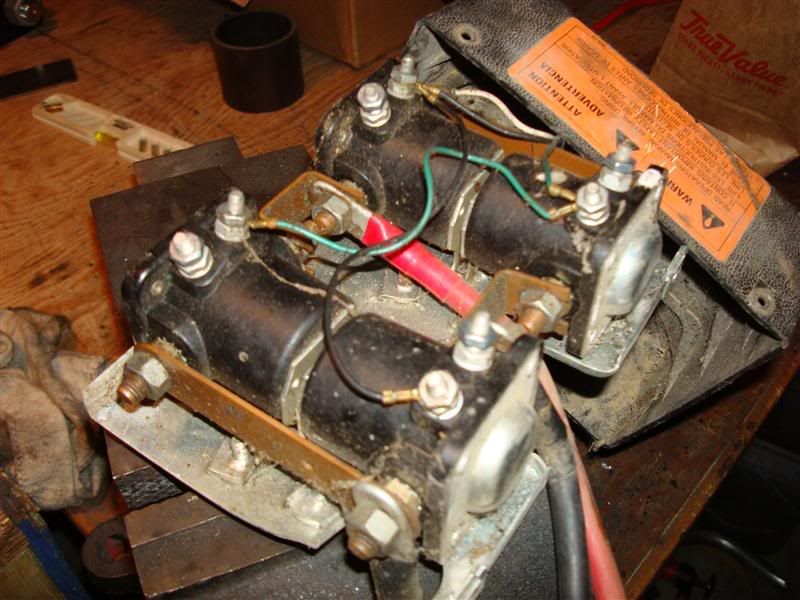

So I recently acquired a Warn A2500 ATV winch. Good buddy of mine got this thing years ago to put on his trailer but never got around to it, so it's just been taking up space. I got the winch, cable, and battery wiring included. Already have a spare hook and remote, and I'll be picking up an old M8000 solenoid box in a few days for pretty cheap.

I had thought about permanently mounting the thing to the trailer, but that would pose a few issues. For one, I'd worry about hitting it when tossing in bigger rounds of wood. Another is I still kinda have an idea kicking around the back of my mind to be able to mount it in the back of the jeep to help lift/drag logs like a 3-point. Thus, I decided on receiver mount. Also, in keeping with the theme of the low dollar project, everything is scrap I have laying around. Even if not ideal, I'm making it work :redneck:

Cute lil thing (Yes that spreader bolt will get replaced)

Later on I'll have to cut a notch out of the bottom board on my wood side front section

Started by cutting apart an old hitch with my favorite (read: only) metal cutting apparatus

I wanted to make sure the assembly could fit into any standard hitch so that dictated how far into the C channel I could place the square stock. A plate was added for reinforcement. And later after the pic more plates were added.

Not having any 2" ID square stock laying around, I did have some scraps of 2x3 box. Cut a notch in one and one side off another.

Then so there wouldn't be any play (and to add extra beef ) I burned in some 1/4" plates on either side making the inner dimensions perfect for a receiver.

) I burned in some 1/4" plates on either side making the inner dimensions perfect for a receiver.

Stuck em together, burned em hot with 6011, and ground the welds to make it prettier once painted so it looks all like one piece. Here is about where it'll sit.

Tomorrow I may add some fish plates over the seams I butt welded. Then I'll burn the whole thing on and add some additional gussets after I bug my neighbor to use his drill press :redneck:

I had thought about permanently mounting the thing to the trailer, but that would pose a few issues. For one, I'd worry about hitting it when tossing in bigger rounds of wood. Another is I still kinda have an idea kicking around the back of my mind to be able to mount it in the back of the jeep to help lift/drag logs like a 3-point. Thus, I decided on receiver mount. Also, in keeping with the theme of the low dollar project, everything is scrap I have laying around. Even if not ideal, I'm making it work :redneck:

Cute lil thing (Yes that spreader bolt will get replaced)

Later on I'll have to cut a notch out of the bottom board on my wood side front section

Started by cutting apart an old hitch with my favorite (read: only) metal cutting apparatus

I wanted to make sure the assembly could fit into any standard hitch so that dictated how far into the C channel I could place the square stock. A plate was added for reinforcement. And later after the pic more plates were added.

Not having any 2" ID square stock laying around, I did have some scraps of 2x3 box. Cut a notch in one and one side off another.

Then so there wouldn't be any play (and to add extra beef

Stuck em together, burned em hot with 6011, and ground the welds to make it prettier once painted so it looks all like one piece. Here is about where it'll sit.

Tomorrow I may add some fish plates over the seams I butt welded. Then I'll burn the whole thing on and add some additional gussets after I bug my neighbor to use his drill press :redneck:

Last edited: