lemme know when the shakedown is scott, if at all possible fit the dipstick evenly between the headers, the swap looks good

:beer:

Thanks! I haven't paid much attention to it now that it's there... I'll look at it when it gets running and hope that I won't have to deal with it. I may have to rethink my bracket.

And then to continue this idea of spending money on something I could have gone a cheaper route the first time...

I went to this fitting place that I was so sure they'd be able to do a million times better than anything I could have done...

And here's what (ready for this?), $80+ dollars got me...

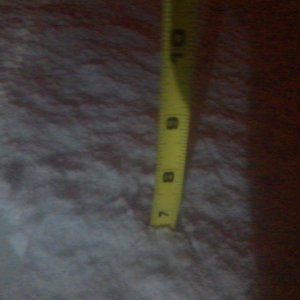

about 30" each in length, Jeep fittings on one end, the two different GM one's on the other...

Well it didn't work

The combination of fittings made it too long and hits hard on the firewall. They got on, but the rubber is soo kinked that it's stupid. They stayed on for ten minutes too long.

Our first request was 90 degree fittings but that wouldn't have shortened them, it actually would have lengthened them. I dunno, I'm thinking I pretty much got ripped off. I'm going to return the fittings that I don't need because we headed to O'Rielly's and bought the Dorman fittings that

ain'tstuckjustresting suggested TWICE! I think it was like $20.00 for both. Since I asked the fitting company to cut the Jeep line and go with all rubber, I'm going to have to use that hose and connect the Dorman fittings to it. The Dorman fittings need to be bent, cut and flared.

It's just one of those things about having the engine those 2" back.

But while at O'Rielly's I did spend more money on the first bling thing I've bought since that Walmart 3 inlet cigarette lighter.

This is top of the line Spectra stuff!! That's O'Rielly's and Walmart blingy-est stuff!! It's way cheaper (quality and cost) than the Airaid DIY kits... And at least they had K&N filter in stock so I didn't have to go somewhere else for that. I was not going to run a Spectra filter. :awesomework:

This looks just as good in a riceburner!

I have to build a few brackets for the fuses from the Howell harness; I'll build a little bracket for this too and weld it to that grill support rod, just like the tranny dipstick.

Intake done!

Now before all this fitting fiasco happened, I finally conquered something that should not have been as hard as it was... But I've said a few times. Nothing really has been easy and that's really what's keeping this so nerve racking.

There it sits! On the table... out at last. All it takes is a mirror, a pair of the tiniest o-clip tool (bent at 90 degrees!) and a completely upside down, curved over the door sill lower back. Since I really only had socket wrenches and a big friggin' hammer I had to work a little harder. It didn't kick my a$$ tho'. I got it. So I pulled out that rod with the retainer welded to it, and it slipped right back into place and tightened the brake pedal back up (they teetered off the same rod).

Now I need to get a footrest for the left side.

As soon as we get the fuel line situated we're about 4-5 wires away from starting it. I can't work on it tomorrow so Friday or Saturday it may get loud without an exhaust :beer: :beer: