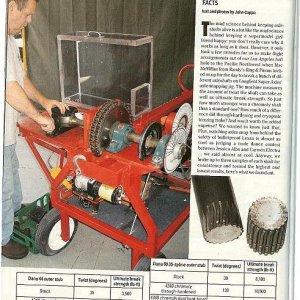

So I had my real first setback. After I got the front shock mounts ready to burn in I for some reason started looking at it closely and without having my new ORI stuts yet I just kinda guessed on the width and frame clearance.

Well it was just too damn tight and I really feared they would hit the frame so I removed what I had just done and tossed it. To achieve the right clearance I would need to outboard the lower mount which meant mounting them on top of the C--which meant the top of the shock mount would need to be higher and at the same time outboard the upper portion of the shock mount.

Well I have been suffering a damn head cold which really made it hard to concentrate on the whole works with the multiple angles.

So I pulled the motor and made a jig to help set everything where it needed to be and got to cuttin tube again.