hjpcummins

Well-Known Member

- Joined

- Oct 11, 2011

- Messages

- 1,510

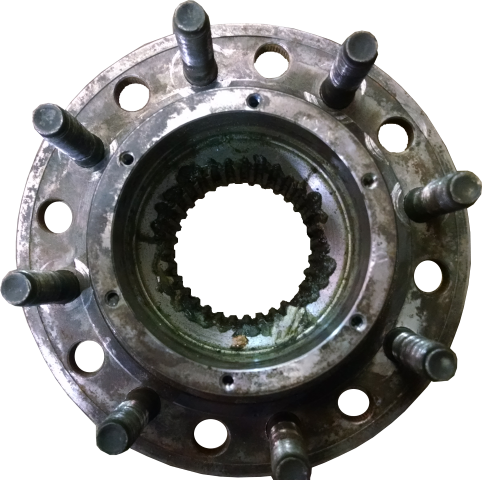

Looking at having my Super duty unit bearings re drilled for 8x6.5, for the sole purpose of locating/selling tyars n whiles.

I know it's been done, just wanting to see if anybody has seen premature failure or any issue from re drilling them.

Also. Can this be done on a standard drill press. Or I'd the material to hard

I know it's been done, just wanting to see if anybody has seen premature failure or any issue from re drilling them.

Also. Can this be done on a standard drill press. Or I'd the material to hard