Love the fork lift set up! That could come in handy alot. I think cutting the fork tips from the bottom would help for things on the ground but cutting from the top would help with picking things up off a trailer. The backstop idea is good and I would set it to keep things from sliding into the winch cable.

:kissmybutt:

That was my first thought with the angle. The forks wouldnt want to dig in as much if the were cut the other way, from my logic.

I'm going to leave the tips how they are for now, if they prove to be a problem, I'm thinking about some slide ins that taper down to a nice point. With inserts, it would be easy to make extensions too.

After finishing up my christmas shopping, and wrapping presents, I managed to sneak in a few hours in the garage.

I made the lifting crossmember, and cut out some tabs for the shackle.

All the way up.. (nice boner bar, huh? :redneck: )

With the hook bottomed on the fairlead, it still has room between the arms and bumper.

All the way down...

And flat...

17" at "flat"

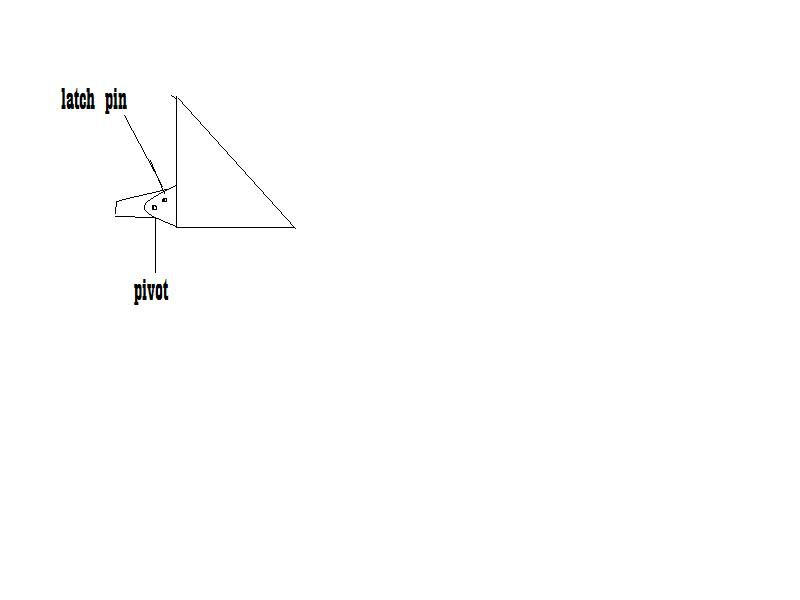

Backstop coming soon......