blacksheep10

XBJRA champ/ 555 and team Nasty codriver

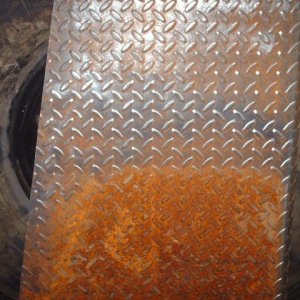

wyatt, I shaved yours to the same point on the housing sides and forward, Hoever, I hatted your plate and coped it. WOW, this guy went nuts as **** in the ring gear. I didn't want to lose strength and go more than 3/16". he went 3/4" down to 9". THAT's HALF A TOOTH!!!

I need to do another for a spare.

I need to do another for a spare.