hokie_yj

Well-Known Member

I should have started a thread for this thing a few weeks ago, but I figured I'd throw one together now.

I know I have another project sitting in the shop that I should be working on. If you're not familiar with it here's the thread for it. http://www.hardlinecrawlers.com/forums/index.php?topic=23417.0 I've been working on it for a few years now, but honestly had gotten burnt out working on it and never getting to ride. I had a perfectly good, running buggy when I started that project but I neglected it focusing all my time and money on the build and eventually ended up selling it. Looking back that was a mistake. So a couple months ago I got the idea to go buy a running rig so I could get out and wheel and hopefully get the motivation back to finish the single seater.

I saw this rig posted here on Hardline and decided to go look at it since it was only about 1.5hrs from me.

The plan was to just go look at it, but out of excitement for a new rig I ended up making a deal with the guy that day. He actually even hauled it home for me. I knew when I got it home there would be a few things I would need to fix, but the deal was good enough that I was ok with it. Once I got it home I found more issues than I originally thought though. I'm not knocking the seller at all though. He's a stand-up guy, and I've talked to him a few times since I got it home. There were just things on it that I wouldn't have been comfortable with taking it out. I just don't like being that guy always breaking down on the trail all the time.

It is what's left of a YJ, I don't remember exactly what year.

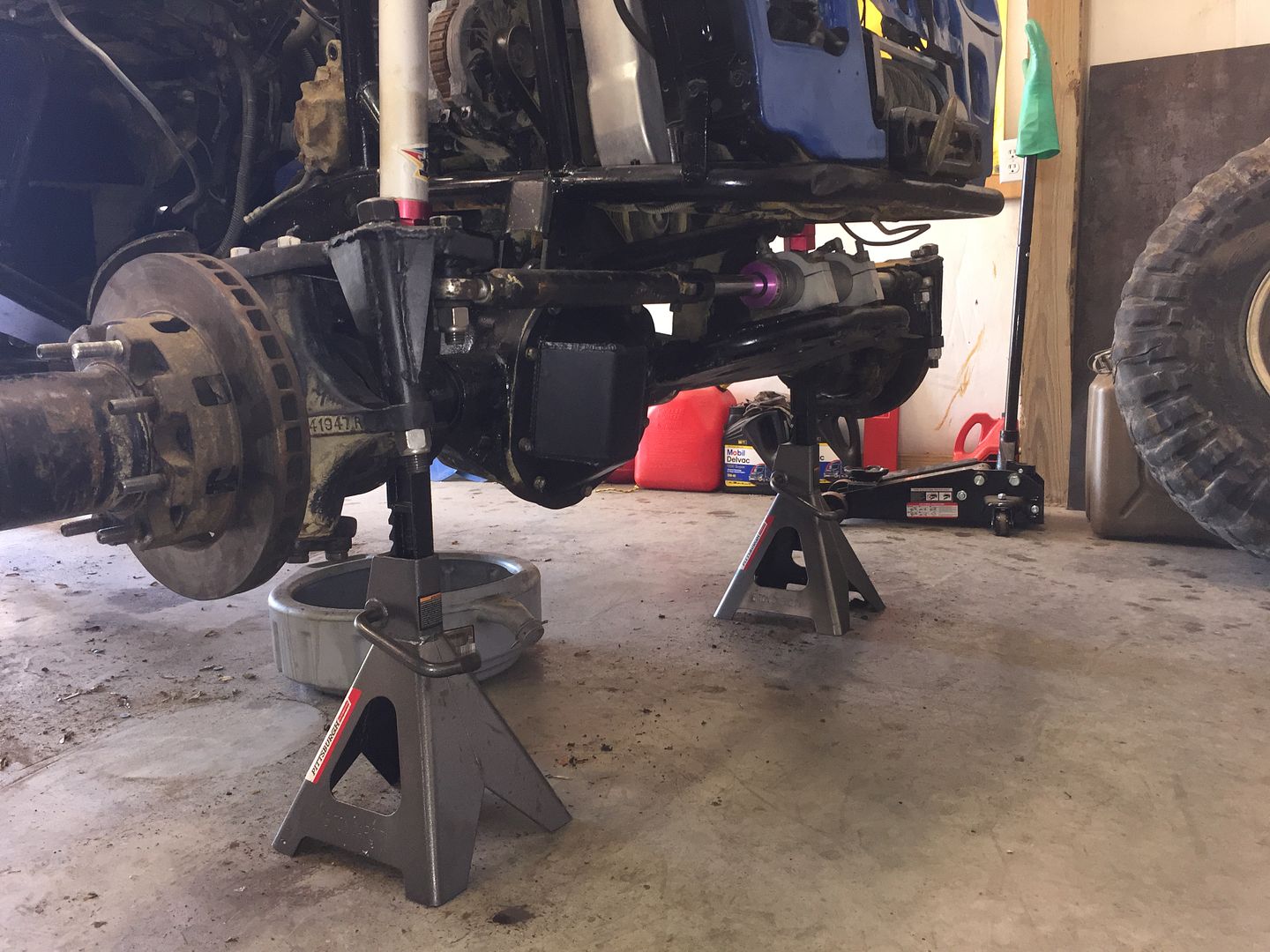

4.0/AW4/D300

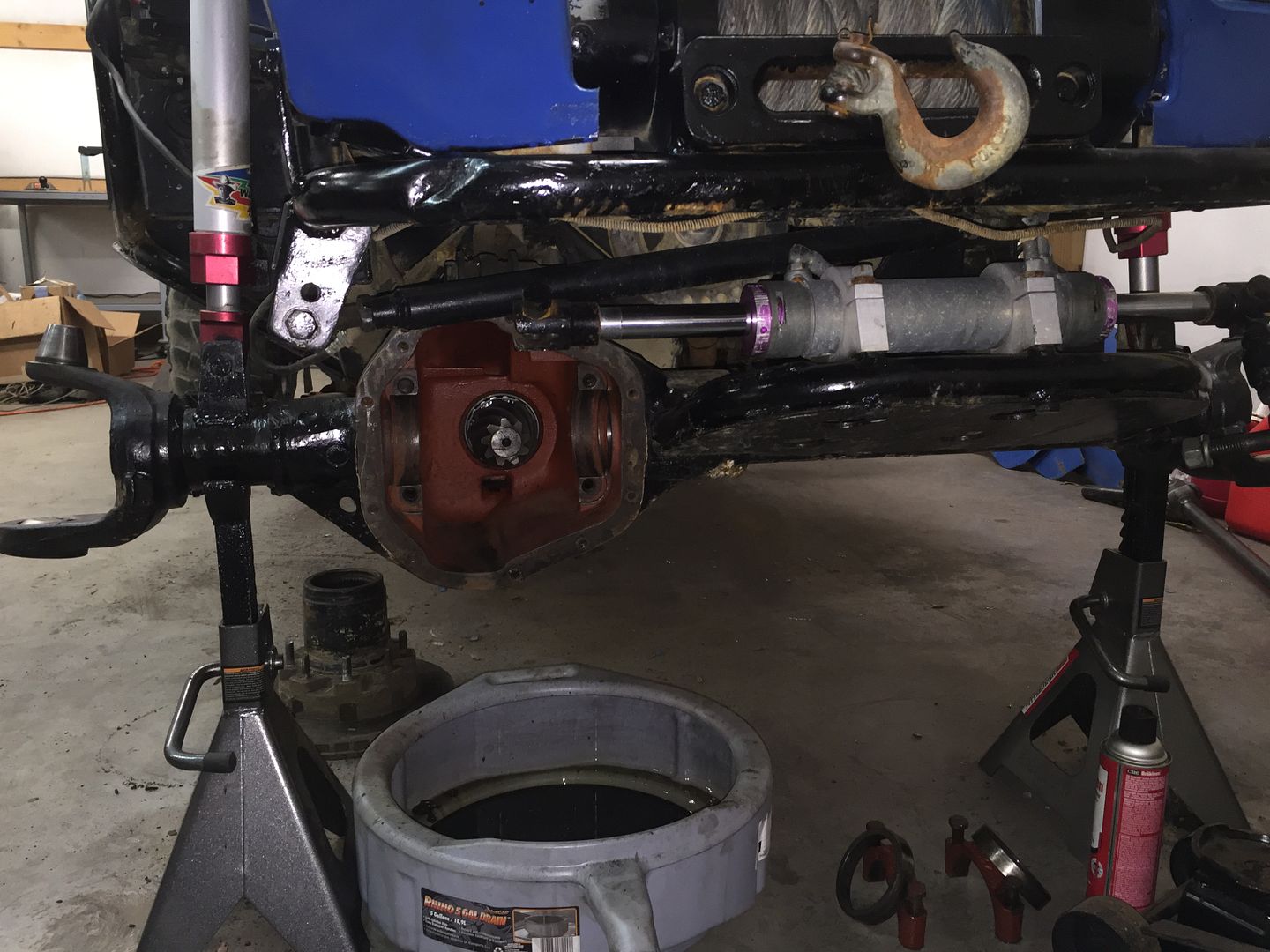

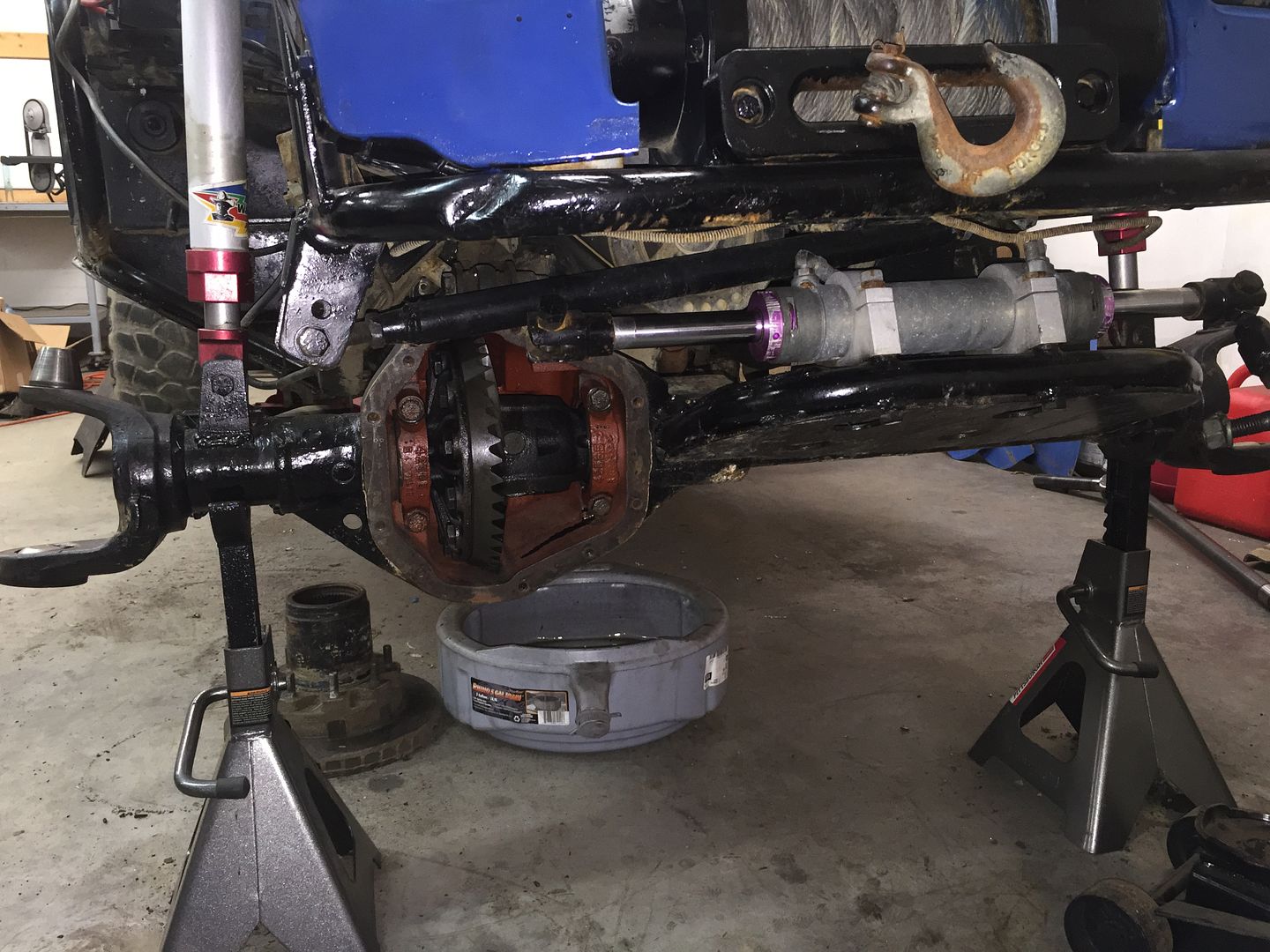

60s F/R 4.56s welded front and spooled rear

4-link F/R with 14" air shocks

I know I have another project sitting in the shop that I should be working on. If you're not familiar with it here's the thread for it. http://www.hardlinecrawlers.com/forums/index.php?topic=23417.0 I've been working on it for a few years now, but honestly had gotten burnt out working on it and never getting to ride. I had a perfectly good, running buggy when I started that project but I neglected it focusing all my time and money on the build and eventually ended up selling it. Looking back that was a mistake. So a couple months ago I got the idea to go buy a running rig so I could get out and wheel and hopefully get the motivation back to finish the single seater.

I saw this rig posted here on Hardline and decided to go look at it since it was only about 1.5hrs from me.

The plan was to just go look at it, but out of excitement for a new rig I ended up making a deal with the guy that day. He actually even hauled it home for me. I knew when I got it home there would be a few things I would need to fix, but the deal was good enough that I was ok with it. Once I got it home I found more issues than I originally thought though. I'm not knocking the seller at all though. He's a stand-up guy, and I've talked to him a few times since I got it home. There were just things on it that I wouldn't have been comfortable with taking it out. I just don't like being that guy always breaking down on the trail all the time.

It is what's left of a YJ, I don't remember exactly what year.

4.0/AW4/D300

60s F/R 4.56s welded front and spooled rear

4-link F/R with 14" air shocks

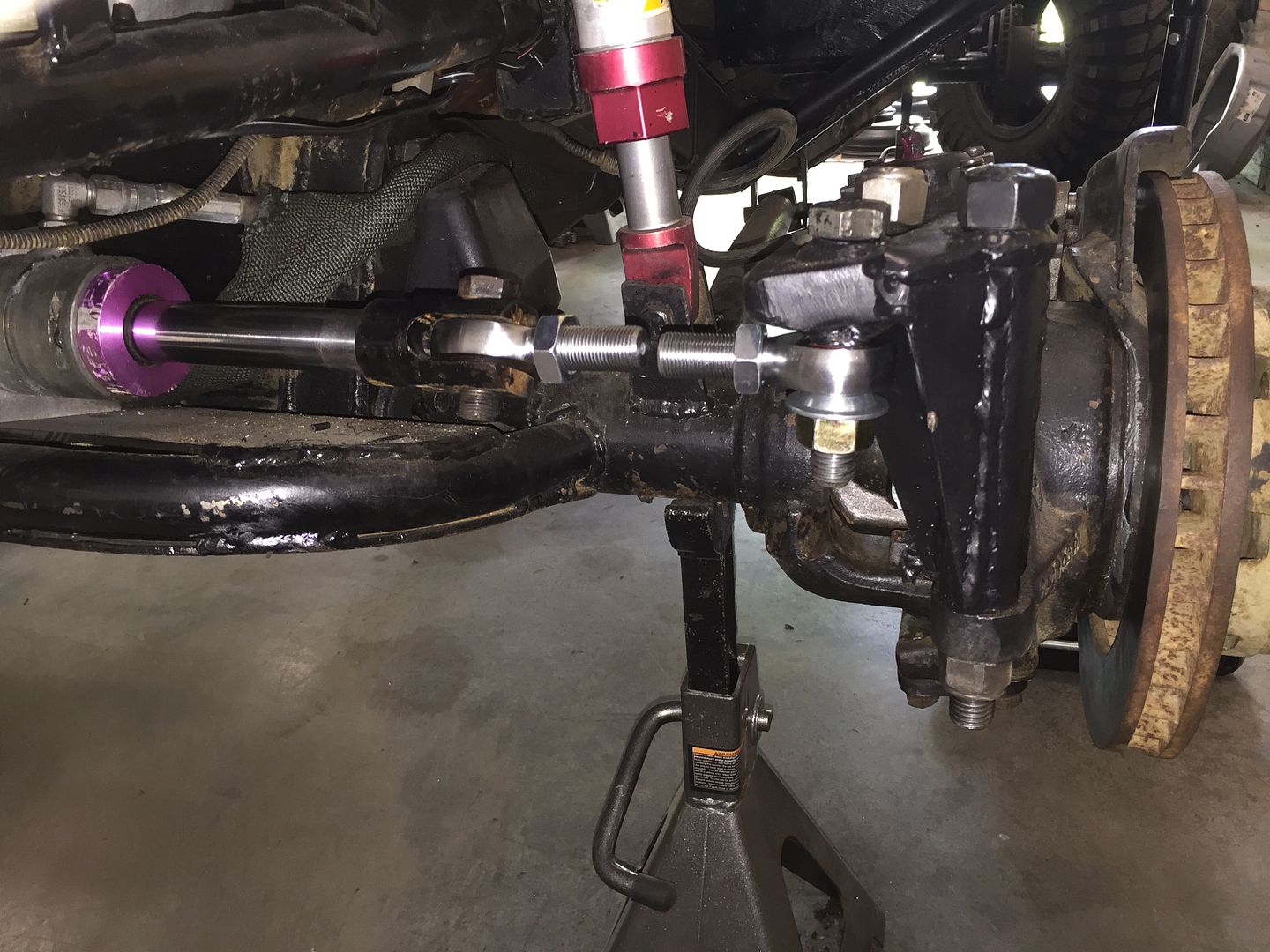

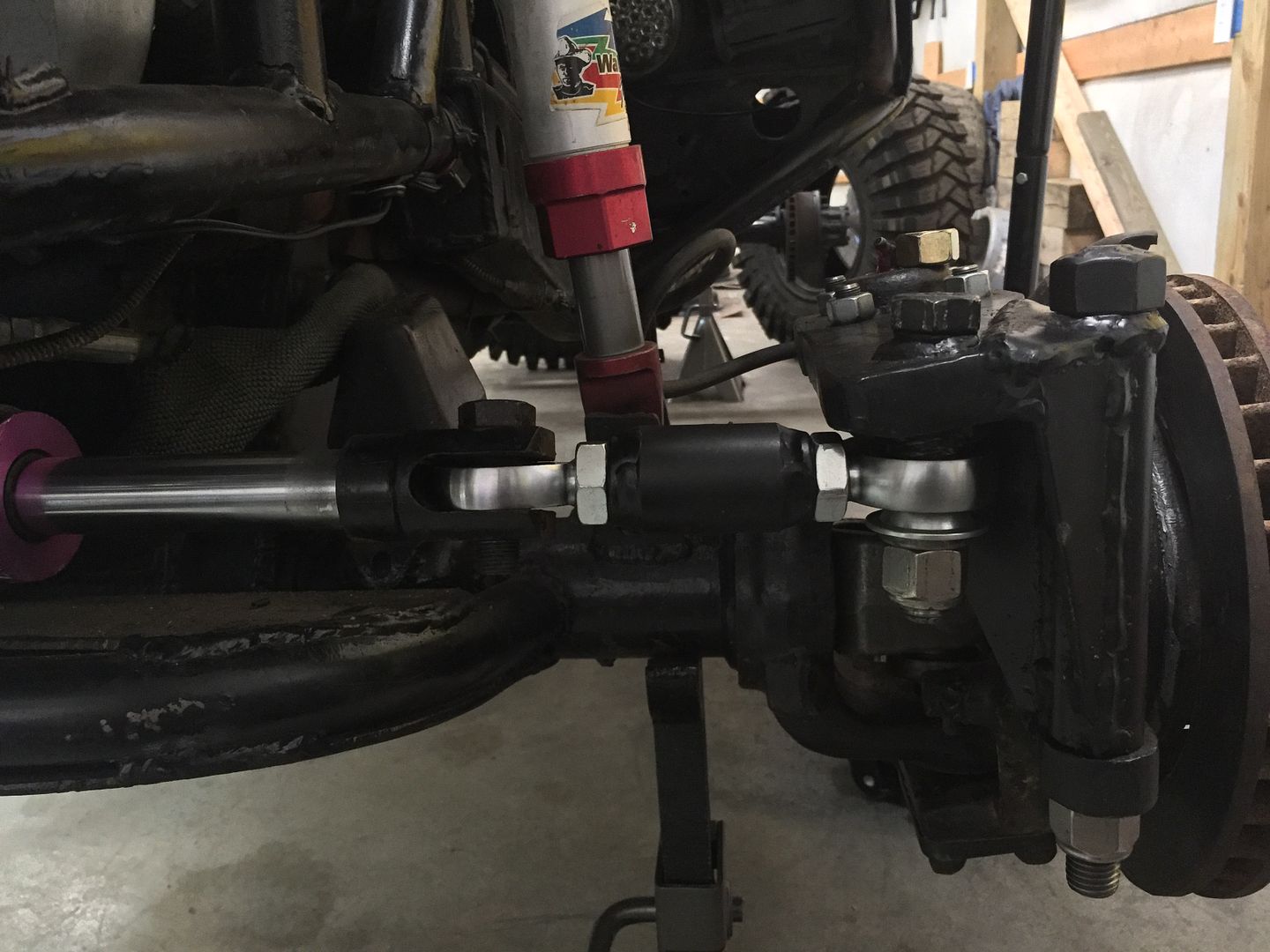

the ram is pretty offset on this axle so the driver side tie-rod is really short, only about 2" of tube. I had ordered the large hex tube adapters from Barnes4WD for both sides but they were too long to work on the short side. So the short side just got standard tube adapters.

the ram is pretty offset on this axle so the driver side tie-rod is really short, only about 2" of tube. I had ordered the large hex tube adapters from Barnes4WD for both sides but they were too long to work on the short side. So the short side just got standard tube adapters.

![IMG_0138[1].jpg](http://attachments.www.hardlinecrawlers.com/xfmg/thumbnail/28/28613-d517dfbfbf498c2ed12103390f99b667.jpg?1652267418)