DHR Darren

Well-Known Member

To even out the distribution, mill the divider out of the intake. It will run way smoother on off camber hard pulls.

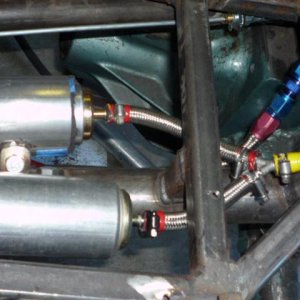

Going to kinda jump around while I figure some things out for the brakes.

Figured I would get the throttle body mounted. Now one thing I did not realize is this is a dual plane intake so each injector will be feeding a bank. I have never experimented with that style of intake and dedicated fuel feed to each bank so I am not sure what to expect.

Also the adapter where the bore holes are, the gasket and the sealing surface at the intake are right at the edge of each other. I used a tab of sealer but I am worried down the road due to hardly any clamping force on the gasket it will fail and suck in--time will only tell there..

But the throttle body is mounted now.