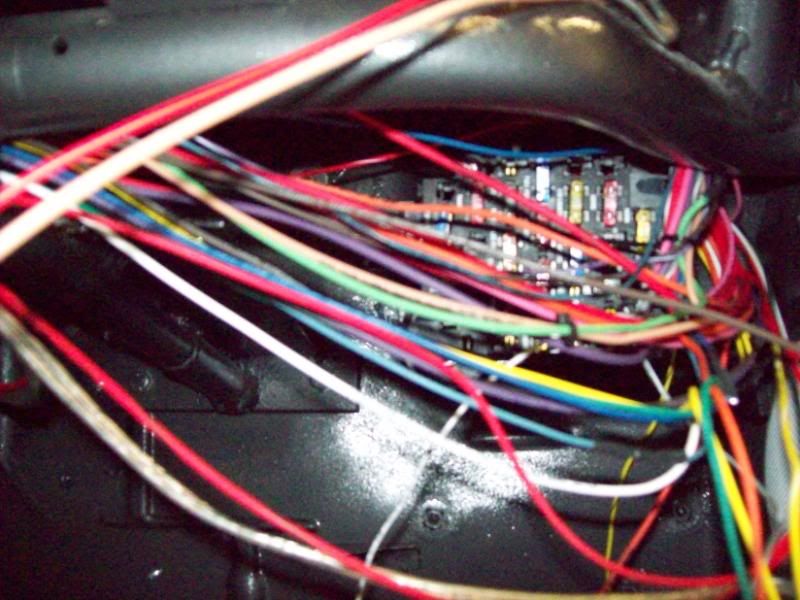

damn I got a mess on my hands

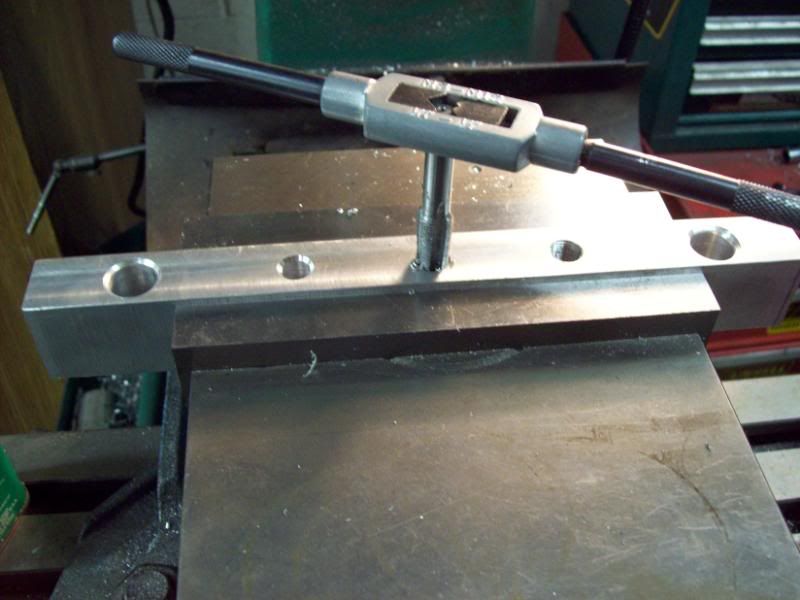

I still got work to do on the dog house gotta fab up one more piece for that and I need to fab some sort of mount for my turn signals.Also need to cut out and drill mount holes and such for the skid plates,few other things includeing all fluids,coolant ,engine,p/s,brake,drivetrain oils.

But I had a freind offer to come by Sunday and help me get started...not quite ready for that but...cant tuen down help!

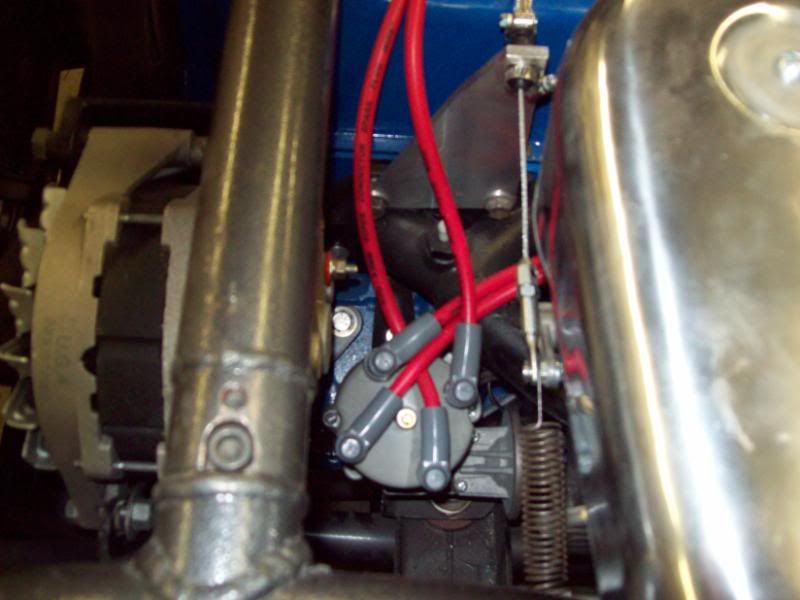

So we started the wireing process.

Im useing an 18 circuit hot rod painless kit.

fuse panel mounted up nice and high.

So we got the gauge panel all wired just need to run a hot wire and aground and rout and hook up the sensor wires(oil press. and water temp)

We got all the differant section laid out and somewhat routed.

Yesterday i took the day off and got a bunch more done.

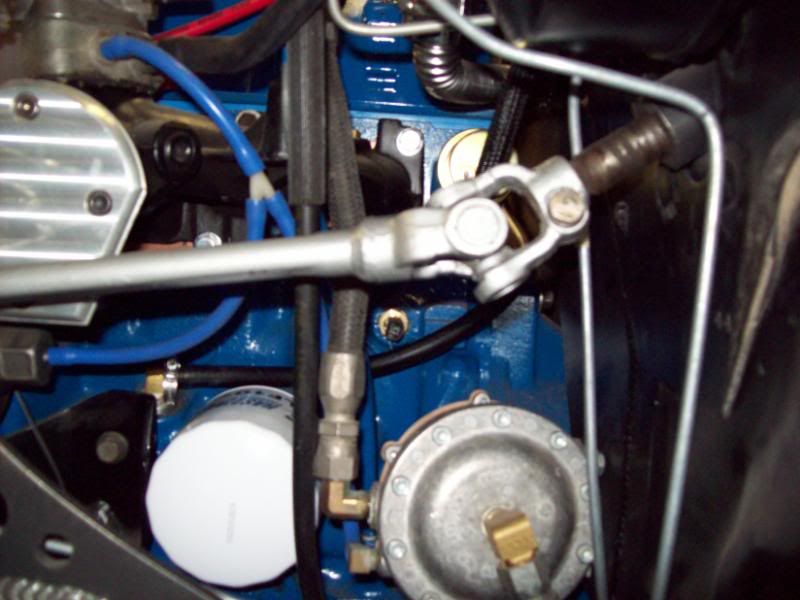

I got all the headlights wired and loomed,starter solenoid,and the fuse panels main power ran,Alt exciter wire and charge wire routed and loomed,Just gotta finish the relay for the high beams,and finish the sensor wires,horn is mounted and wired.

Then I started on the back...kinda working my way outside to in...not sure if that proper...I really dont know what im doing as usual lol well I do know what im doing...trying to build a damn zuk lol I think you get my drift.

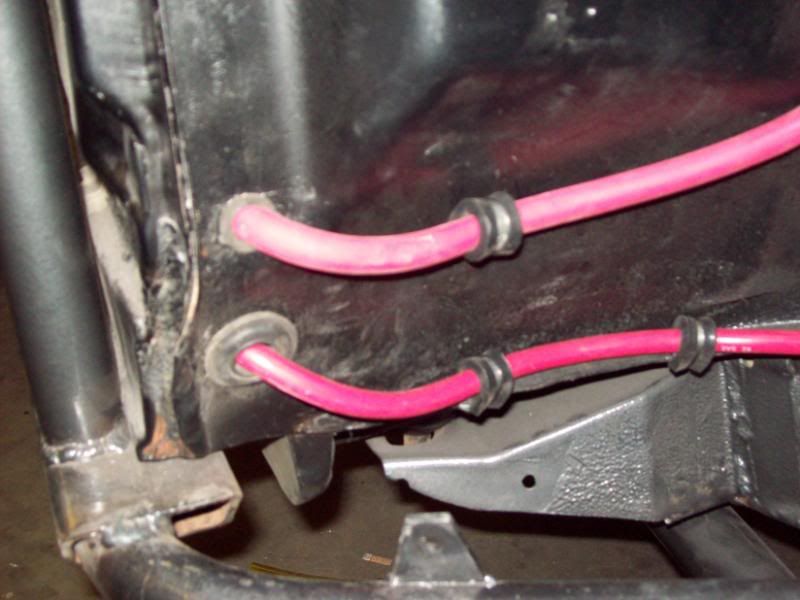

Got the rear main wires ran and loomed,Dome light is done,rear speakers are done,rear tail lights,brake,turn,back up lights are all routed and loomed.Just need to wire up the arb and run some wires up to the dash switchs and threar is all done...had a very productive day...just got in a zone,had the metal cranked up and got down lol

At first I was hating this **** but ive kinda been enjoying it actually.:awesomework: