zjtrey

Well-Known Member

few updates… had a 4 day weekend and made some good progress…

got my skid plate all welded up and turned her back over… put the axles back under and she's a roller

me next to it so you can get an idea of its size..

got the orbital mounted..

some front bumpstops

rear bumps… i didn't get a pic of the pads all finished out..

got my skid plate all welded up and turned her back over… put the axles back under and she's a roller

me next to it so you can get an idea of its size..

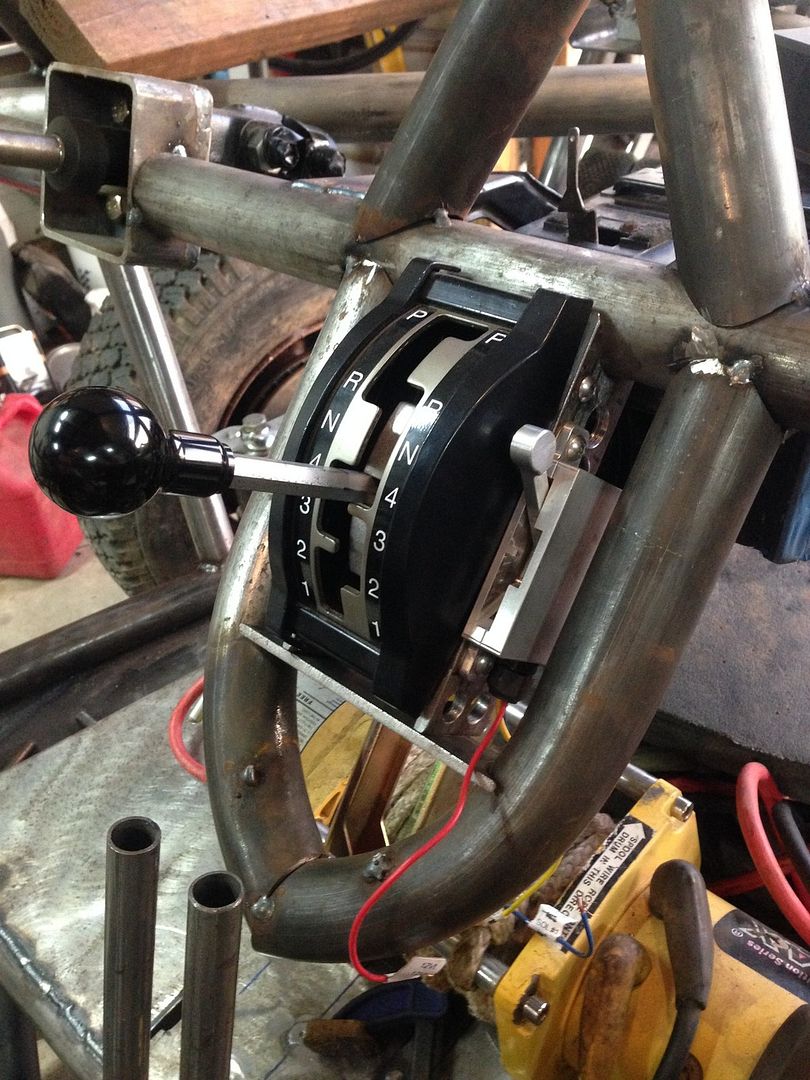

got the orbital mounted..

some front bumpstops

rear bumps… i didn't get a pic of the pads all finished out..

gonna run it a few times without paint then tear down for blasting and a professional paint job.. I'm thinking of painting the chassis a blue color close to the color of the shock hardware with white panels…. any suggestions on that?

gonna run it a few times without paint then tear down for blasting and a professional paint job.. I'm thinking of painting the chassis a blue color close to the color of the shock hardware with white panels…. any suggestions on that? .

.