617_Racing

Well-Known Member

Well...

I guess it's time to start bending some tube and try to make a buggy. "Wanna Be" came from the fact that I want it to be a bouncer, but I doubt it'll actually be on that level.

Specs will be:

383 mild build; aluminum head, roller rocker bling, RV cam for now, propane

TH350 full manual reverse valve body

203/205 ORD doubler

D60 front; 5.13 with grizzly

14 bolt rear; 5.13 welded, disc brakes

42" TSL on 15" beadlocks.

Some comfy Corbeau seats

2.5" C/O.... Don't have them yet but thinking 16" all the way around.....

Last but not least a big pile of tube. Lower main rails will be 1.75 x .188 wall DOM and the rest will be 1.75 x .120 wall HREW.

So to get started. Spent 4ish years to build up my Yota with the drive train above and tore it completely down in one day.... Why wasn't it that easy to build it?

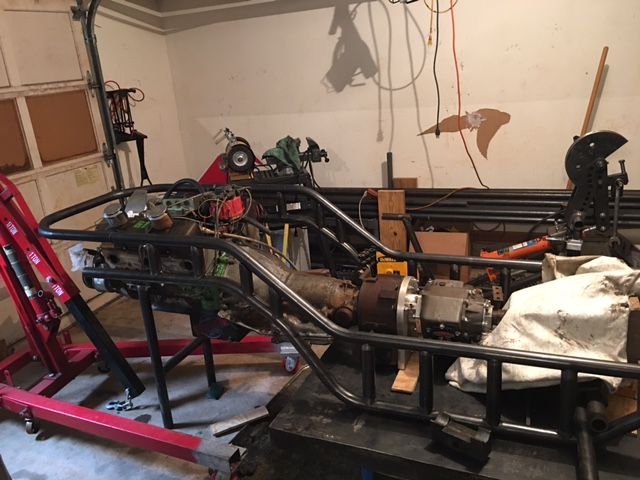

So far I've got a little chassis table set up and got the engine, trans and tcases on it. Made some legs to hold the engine up so I can slide it off the front a little more once I start laying everything out.

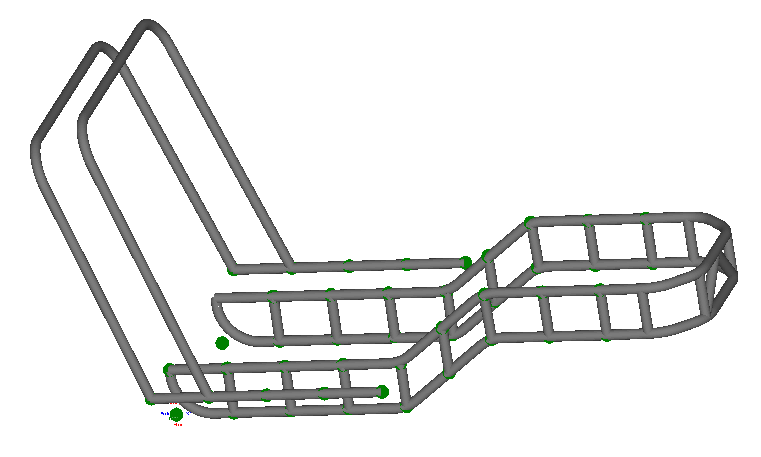

Once I get my buddy's four wheeler fixed up for him, I'll get everything in the center and start laying stuff out in bendtech.

It'll be slow to start off, but once I get that fourwheeler out of here I hope to get rolling on it.

I guess it's time to start bending some tube and try to make a buggy. "Wanna Be" came from the fact that I want it to be a bouncer, but I doubt it'll actually be on that level.

Specs will be:

383 mild build; aluminum head, roller rocker bling, RV cam for now, propane

TH350 full manual reverse valve body

203/205 ORD doubler

D60 front; 5.13 with grizzly

14 bolt rear; 5.13 welded, disc brakes

42" TSL on 15" beadlocks.

Some comfy Corbeau seats

2.5" C/O.... Don't have them yet but thinking 16" all the way around.....

Last but not least a big pile of tube. Lower main rails will be 1.75 x .188 wall DOM and the rest will be 1.75 x .120 wall HREW.

So to get started. Spent 4ish years to build up my Yota with the drive train above and tore it completely down in one day.... Why wasn't it that easy to build it?

So far I've got a little chassis table set up and got the engine, trans and tcases on it. Made some legs to hold the engine up so I can slide it off the front a little more once I start laying everything out.

Once I get my buddy's four wheeler fixed up for him, I'll get everything in the center and start laying stuff out in bendtech.

It'll be slow to start off, but once I get that fourwheeler out of here I hope to get rolling on it.