-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Buggy build "Indecision"

- Thread starter pholmann

- Start date

ldudley

Well-Known Member

awesome ! I know the feelin .... I don't get to fool with mine much lately either .

pholmann

Well-Known Member

I'm going on vacation tomorrow for a week. I'm bummed because I won't get to work on it. Retarded right? lol.

kushKrawlin

Well-Known Member

Hell no. I'd Prob drive seperate knowin my selfish ass. Fukin terrible time for vacation!! U have been killing it Tho. It's getting there now!! Awesome.

kmcminn

Well-Known Member

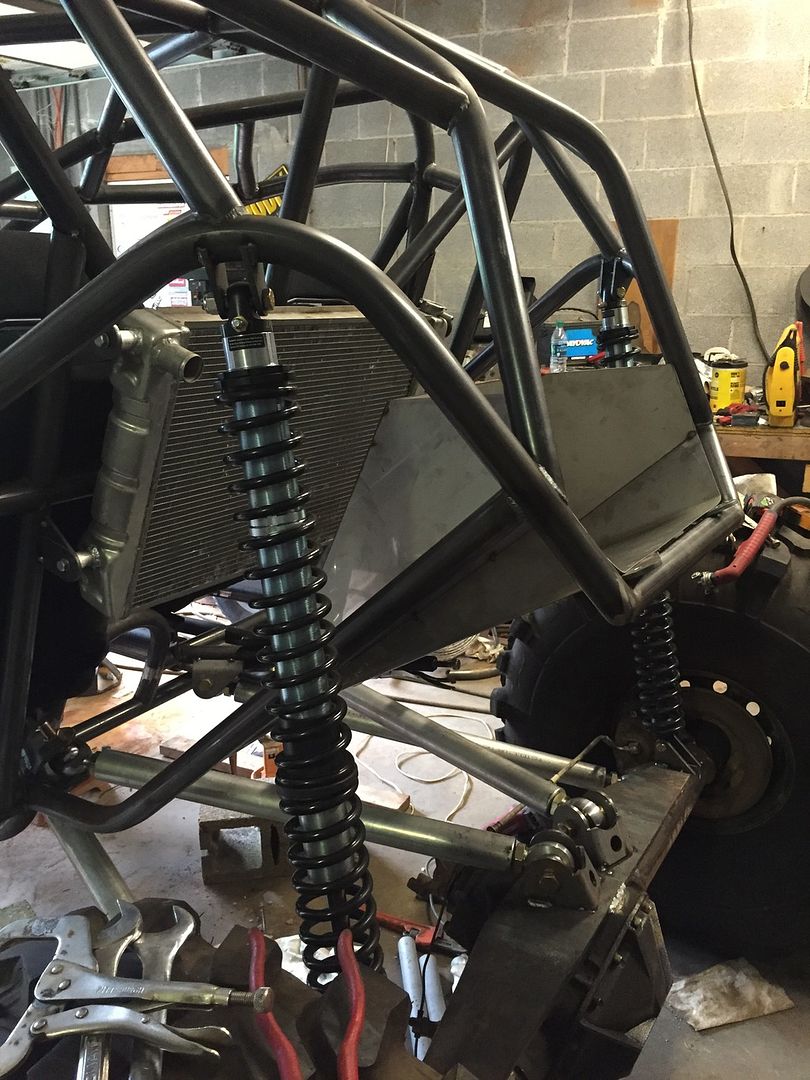

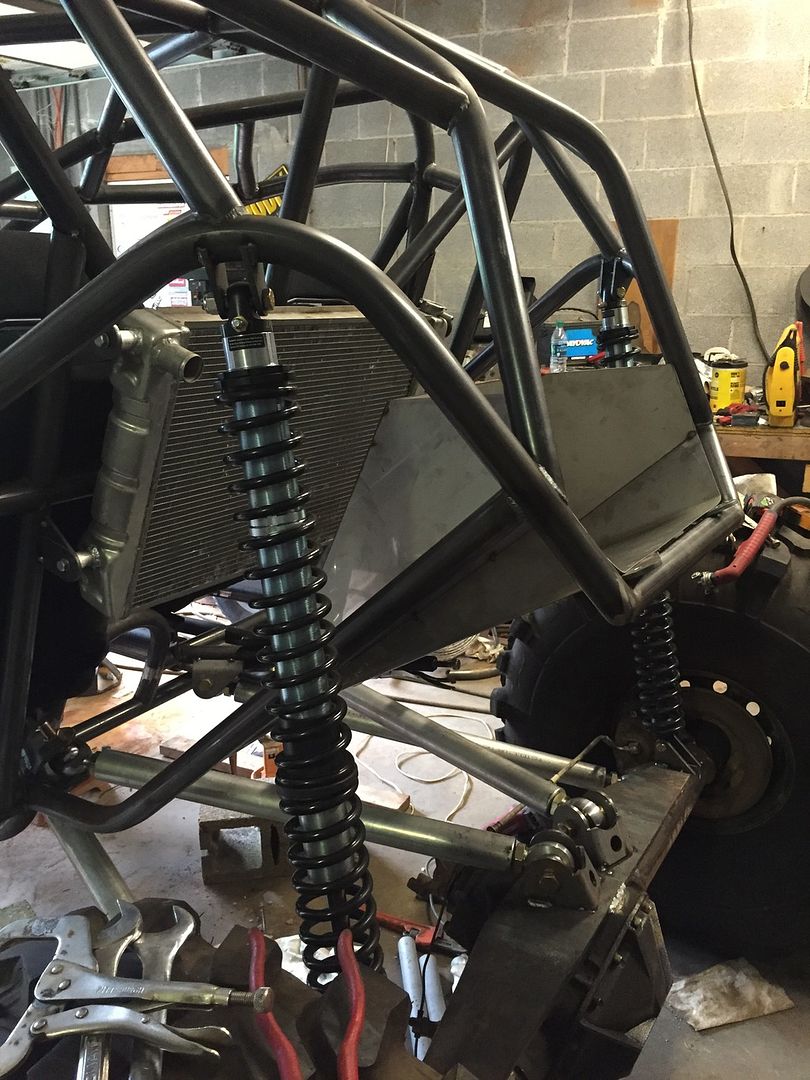

Pholman, the buggy is looking good. I am seeing how you have you shocks mounted. Seems like most of the time people run the eyes of the shocks 90° apart. Where the top shock bolt is pointing toward the engine the bottom shock bolt is running from front to back on the rig or vice versa. I have always heard you do it like that to keep them from binding and breaking the shock. I noticed a blue Rockwell buggy on here is like done like yours, I was going to mention in his build but thought I needed to look around a little first. I started looking on WOD instagram and all his builds the shock eyes are 90° apart. Just something I think you should look into. It would be great for some of the reputable builders or tech gurus to chime in.

pholmann

Well-Known Member

Thanks Casey. I know it's killing me to have to leave.

Kevin, I'm all ears. I may need to turn them. For some reason it made sense at the time. I think because They are laid back quite a bit. I didn't even take into account the twist during articulation. I'll look at it when I get back from vacation and see. Good call I'm open to suggestions hints and tips from anyone that knows more than I do, which isn't hard to achieve.

Kevin, I'm all ears. I may need to turn them. For some reason it made sense at the time. I think because They are laid back quite a bit. I didn't even take into account the twist during articulation. I'll look at it when I get back from vacation and see. Good call I'm open to suggestions hints and tips from anyone that knows more than I do, which isn't hard to achieve.

kmcminn

Well-Known Member

pholmann said:Thanks Casey. I know it's killing me to have to leave.

Kevin, I'm all ears. I may need to turn them. For some reason it made sense at the time. I think because They are laid back quite a bit. I didn't even take into account the twist during articulation. I'll look at it when I get back from vacation and see. Good call I'm open to suggestions hints and tips from anyone that knows more than I do, which isn't hard to achieve.

If you are like me I can't afford to go ruin a set of coilovers. Buggy looks great.

pholmann

Well-Known Member

No I cannot. Thanks for the compliments and for the heads up.

al1tonyota

Well-Known Member

I did chime in!kmcminn said:Pholman, the buggy is looking good. I am seeing how you have you shocks mounted. Seems like most of the time people run the eyes of the shocks 90° apart. Where the top shock bolt is pointing toward the engine the bottom shock bolt is running from front to back on the rig or vice versa. I have always heard you do it like that to keep them from binding and breaking the shock. I noticed a blue Rockwell buggy on here is like done like yours, I was going to mention in his build but thought I needed to look around a little first. I started looking on WOD instagram and all his builds the shock eyes are 90° apart. Just something I think you should look into. It would be great for some of the reputable builders or tech gurus to chime in.

Eddyj

Well-Known Member

I think I'm "blue rockwell buggy", maybe not. Both of my bolts run with the frame,where as yours run with the axle. I originally tried that but had to much articulation in the axle. it took me almost an entire night of cycling the front axle to get zero bind. In fact I made temporary brackets on the axle end until I got the angle correct. Somehow, I forgot to beef them up, until I read this.

Good looking build

Good looking build

Re:

No guru here, but the 90* is mainly for packaging on the upper mounts. On the lowers, the bolt should go in front to back as that allows the shock mount more range of motion. Flexing the suspension while mocking up the shocks allows you to see potential binding. Shocks with high mis-spacers net about 35* where shocks like Fox that use the little spacers net a bunch less.

Mounting the two eyelets 90 off is negated by the shaft being able to spin in the body.

But I dunno...

No guru here, but the 90* is mainly for packaging on the upper mounts. On the lowers, the bolt should go in front to back as that allows the shock mount more range of motion. Flexing the suspension while mocking up the shocks allows you to see potential binding. Shocks with high mis-spacers net about 35* where shocks like Fox that use the little spacers net a bunch less.

Mounting the two eyelets 90 off is negated by the shaft being able to spin in the body.

But I dunno...

pholmann

Well-Known Member

Cool. Lots of things to look at when I get released from vacation.

Beerj

Sonzabitches!

I would think it kinda depends on the shock angle front to back. If they're fairly straight up and down then I'd say mount the bolts parallel with the frame since you'll have more variation in the C/O to axle relationship. If you're flex nets you a 45° angle between the frame and axle, then you'll have damn near 45° difference between the axle and C/O which you might only achieve with pivoting on the bolt rather than the spacer

5BrothersFabrication

Zzzzz....

pholmann

Well-Known Member

Well after 4 weeks of torturous work and chores I finally got a little time to work on my new buggy. Also got a little motivation watching the bounty hill yesterday. The next major thing to do is build my fuel cell which I got most of the way done today. Lucky for me I gave the wife my cold I had all last week so she just wanted to veg on the couch and I got some garage time.

pholmann

Well-Known Member

Got all the pieces on or cut and waiting. Now waiting on my rollover valve, fill neck and hydramat. Then I can fit the inside stuff and weld it up.

tonybolton

Bypass Crawler

Re:

Damn....never seen anyone use $100's as oil-dry before......you DA man!!!

Damn....never seen anyone use $100's as oil-dry before......you DA man!!!

pholmann

Well-Known Member

I may as well, they don't hang around long enough to feel like I even had them anyway.

kmcminn

Well-Known Member

How many gallons of gas will it hold.

pholmann

Well-Known Member

Looks to be about 12 gallons. I won't know for sure until its welded up. I'm sure there is some algebraic equation that will tell me, but I'll be the first to tell you I'm not mathematically smart enough to figure it out. I'm hoping for 12 though. Its pretty decent size. I just hope the odd shape doesn't cause me to think its bigger than it is.