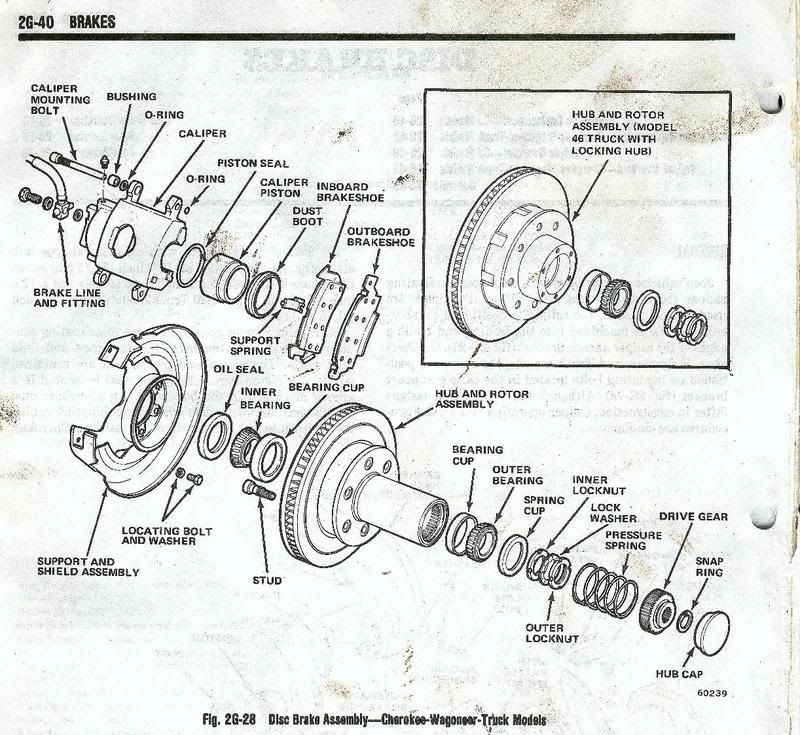

phew, still battling allergies, but got some more work done. long story short, all i have left to do is hook up the brake lines and bleed them (yay for speed bleeders), make some spring plates, and go get some degree shims for castor. ill be picking up a set of 4*, 6*, and 8* and seeing which one will work. im thinking 6* just by eye ball.

shock towers welded in. hung like a monkey from one of them, and it didnt budge, so i probably wont gusset the back side, way to much work to get back there and im lazy.

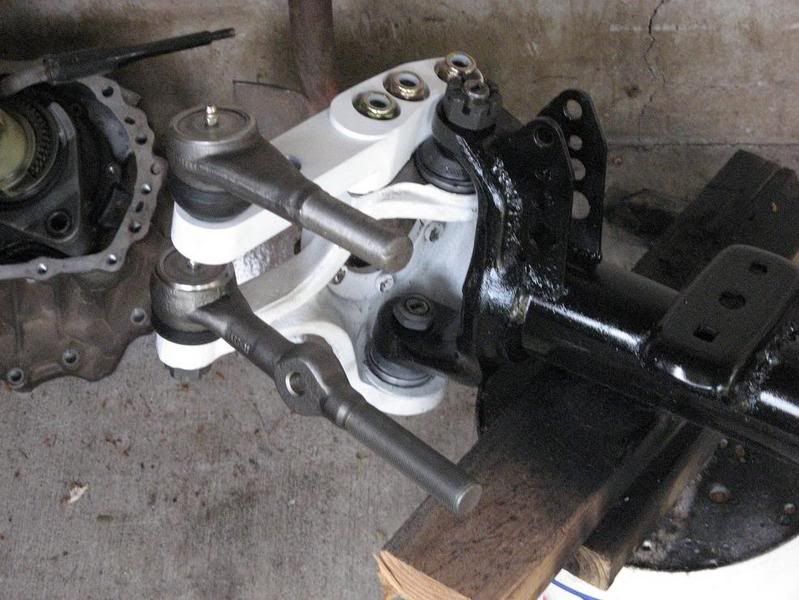

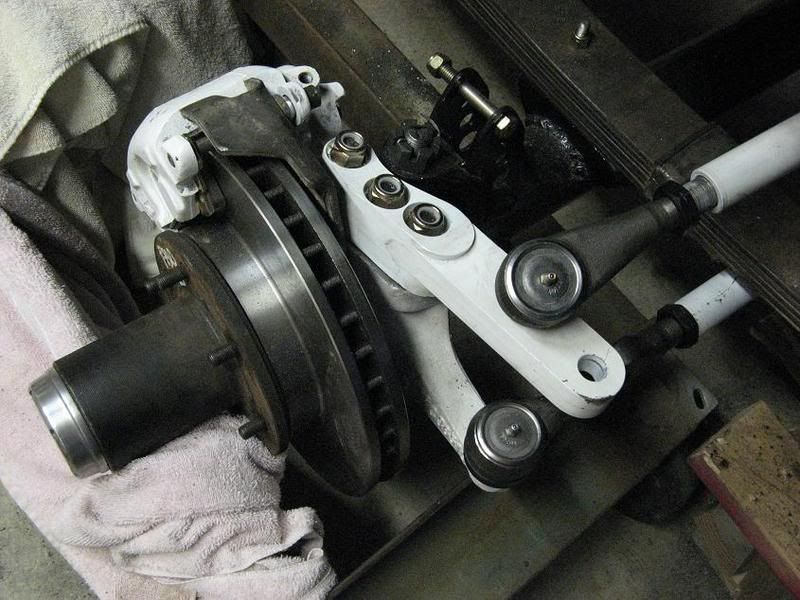

pass side looking towards drivers. my set of Bunk draglink/tie rod are perfect. just had to trim an inch off each TRE to make my toe right, didnt have to mess with the draglink ends at all. all 1 ton chevies ends btw

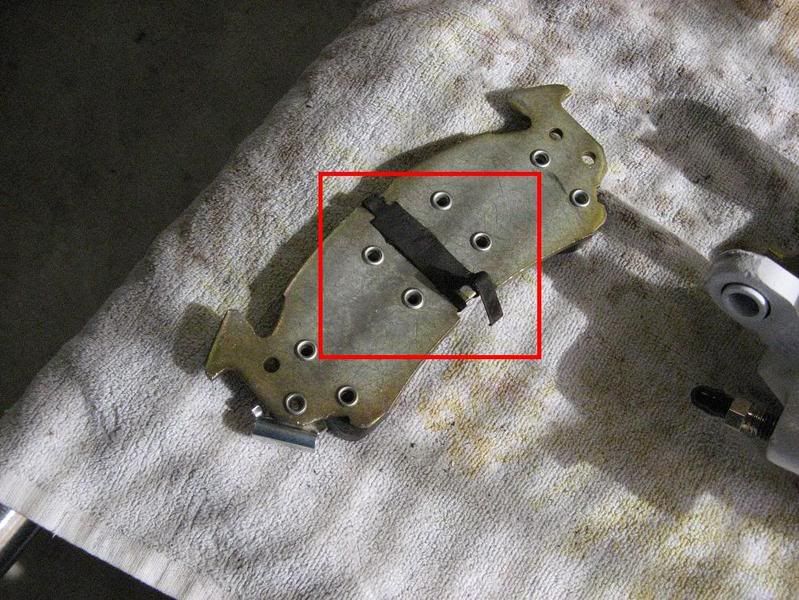

passenger side flat top with all the crap on it.

driver side looking towards pass. after mocking up the axle yesterday and using the center hole in the spring bad, i decided the drill out the back hole and move the axle forward 1.5" to get the tire out of the firewall.

aprox. shackle angle, will be alittle more towards the frame when all the weight is on the springs and i throw my bumper back on.

what it should look like. wb is at 106" right now, but after long arming the rear, itll be closer to 108"-109". cool beans!

added some horsepower to move these big ass tires. i havent dynoed anything yet, but i think it gained 36hp. i know, awesome.

hope to get this out and driving tomorrow, cross your fingers.