PHILLBILLY1

Well-Known Member

Scaleready? Yep, that is the name of my business.:awesomework: I am now a vendor on RCCrawler.com, building custom chassis' and body protection.

So this is what I have been up to on the side......

I am building a Tundra bodied 2.2 scale crawler......well, kinda scale.....:redneck:

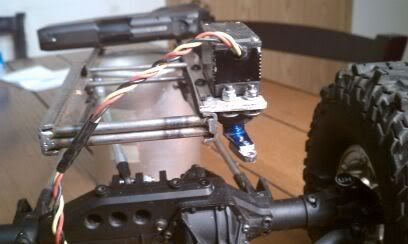

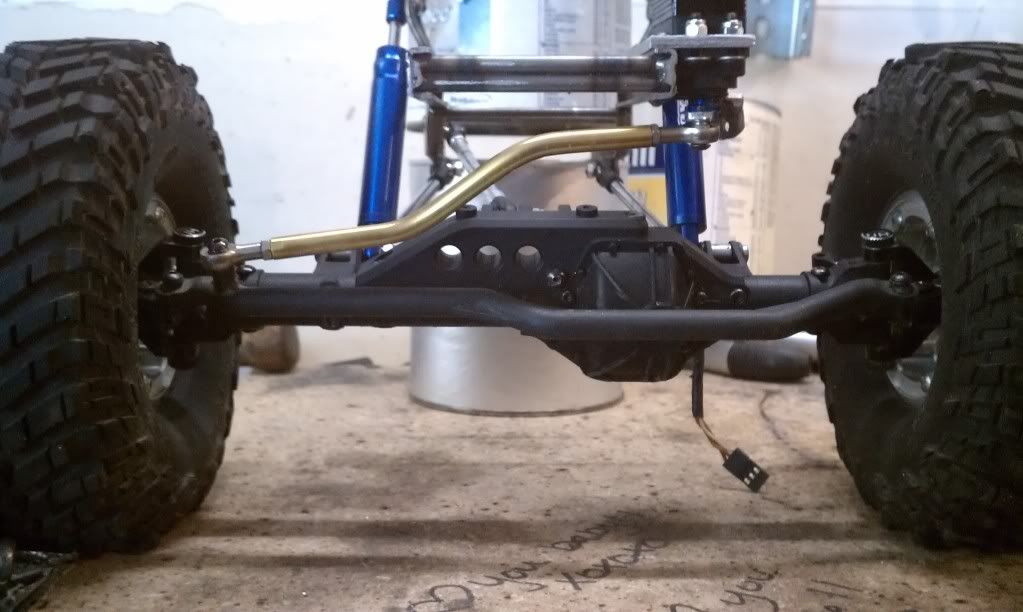

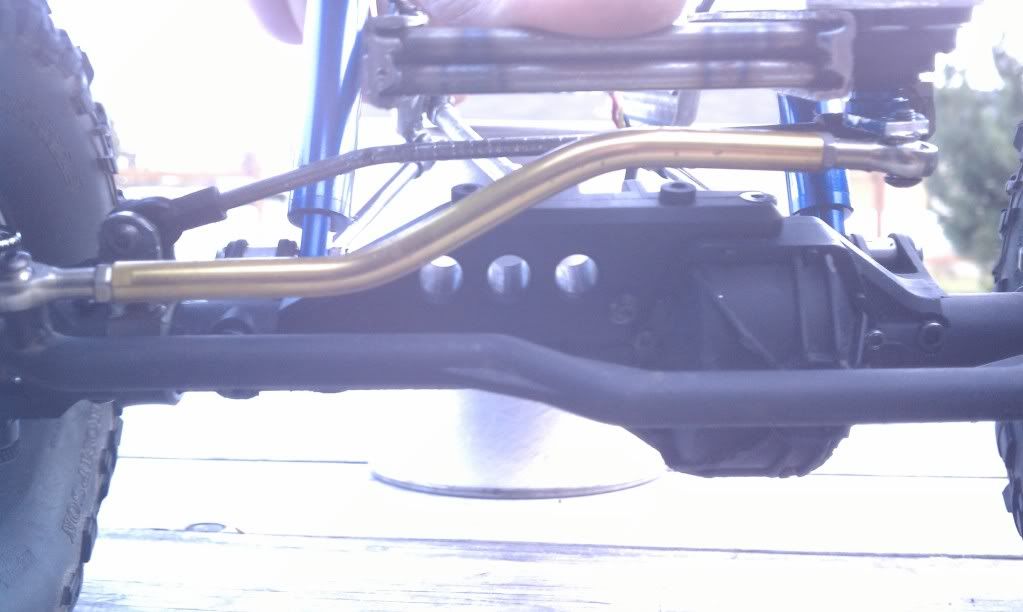

Got some wraith axles for this build:awesomework:

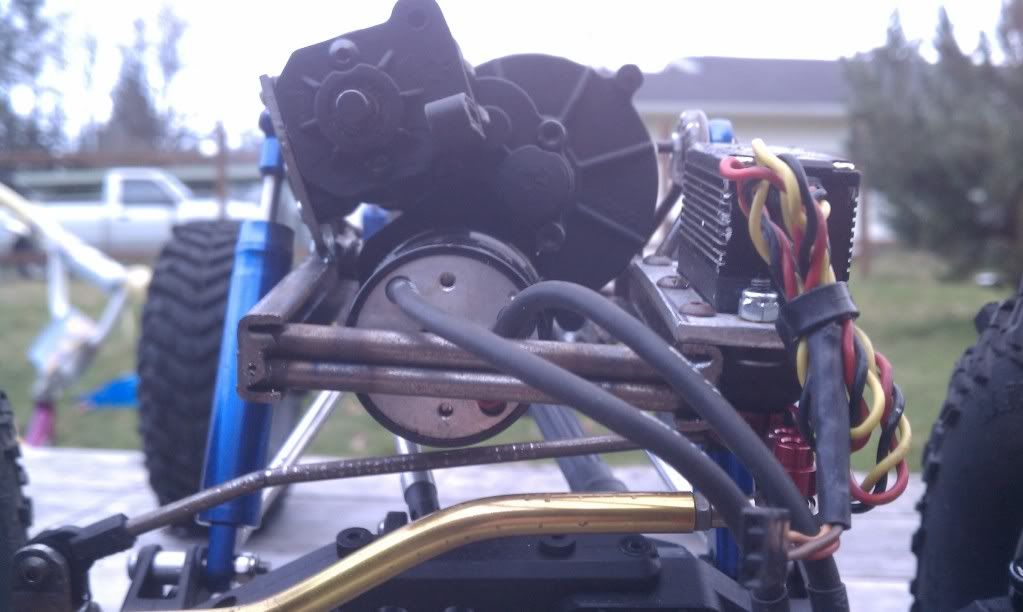

Started the frame. It's going to be c-channel frame to the back of the cab, then tube from there on.

So this is what I have been up to on the side......

I am building a Tundra bodied 2.2 scale crawler......well, kinda scale.....:redneck:

Got some wraith axles for this build:awesomework:

Started the frame. It's going to be c-channel frame to the back of the cab, then tube from there on.

Last edited: