My New cj7 project...Maybe my last, cause I really regret selling my cj5. So I plan to keep this one forever! I picked this "beauty" up off Craigslist for a nice price. It's not perfect but she aint too bad either. Someone started a 4.0efi swap on it but wasn't able to get spark. Well after days of tracing wires, checking grounds, and testin sensors I found when they did the AA cps relocation kit they crossed a wire, heat shrank about six inches of the splice made damn near impossible to find coming in on someone's "handy work". Now I have spark but not getting fuel through the injectors. I think it's a lack of fuel pressure. Any way I'm working on it. In the mean time i'm working on axle swaps and suspension mods. here is a quick list of the mods in mind for now.

4.0EFI for now

Stock T-5:screwy:

Dana 300 w/clocking ring, twin stick, and 4:1, and a tummy tuck

Waggy 44 front center section with 3/4 ton f250 outer knucks. About 63wms-wms (I will confirm later)

Dana 60r Narrowed to match front wms-wms

H2 wheels 17x9

37" Goodyear Kevlars

Soa w/yj 2" springs (4" on now but trading for lcg)

Basic, budget, but effective. check da pics. Don't worry kinda in mock up stage now, every thing will get beef and gussets.

Pic of the Ford Knucks on rollers. They are external hubs, I don't love it but you cant hate free.:banana:

Waggy knuck getting ready to be chaged out.

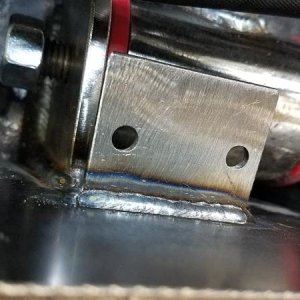

Suspension is just tacked for mock up right now. My little 110 welder kinda sucks for this size metal. Will all get welded up with a nice 220 Miller machine

Yikes what a mess! I have all the loom, tape, and zip ties cut out to chase wires. This will get lots of attention very soon. It will be nice and clean.

Dana 60...Free:banana:

Other Dana 60 with disc conv. It was for a diff project years ago but was never used. I'm going with the "use two to make one theme here:bangtard:

4.0EFI for now

Stock T-5:screwy:

Dana 300 w/clocking ring, twin stick, and 4:1, and a tummy tuck

Waggy 44 front center section with 3/4 ton f250 outer knucks. About 63wms-wms (I will confirm later)

Dana 60r Narrowed to match front wms-wms

H2 wheels 17x9

37" Goodyear Kevlars

Soa w/yj 2" springs (4" on now but trading for lcg)

Basic, budget, but effective. check da pics. Don't worry kinda in mock up stage now, every thing will get beef and gussets.

Pic of the Ford Knucks on rollers. They are external hubs, I don't love it but you cant hate free.:banana:

Waggy knuck getting ready to be chaged out.

Suspension is just tacked for mock up right now. My little 110 welder kinda sucks for this size metal. Will all get welded up with a nice 220 Miller machine

Yikes what a mess! I have all the loom, tape, and zip ties cut out to chase wires. This will get lots of attention very soon. It will be nice and clean.

Dana 60...Free:banana:

Other Dana 60 with disc conv. It was for a diff project years ago but was never used. I'm going with the "use two to make one theme here:bangtard:

Last edited: