SomewhiteGuy

Well-Known Member

- Joined

- Apr 10, 2013

- Messages

- 486

Thanks.

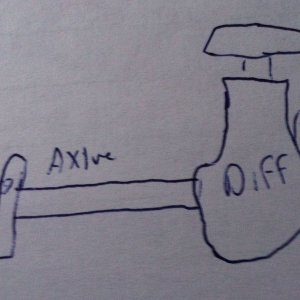

Other end of midship shaft.

Done.

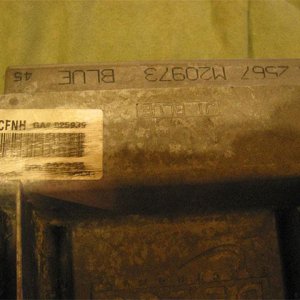

Made a bracket and mounted it in there, not Ideal by the book but this 1410 stuff is huge compared to the toyota shafts I am used to.

Kid ninjaed a pic while I was welding out passenger header.

Ran out of argon with half the collector to go.

Hadley added grab handles and steering wheel hanger.

Also built a mount for the overflow tank.

We quit early today to do some suspension tuning on the rzr.

Other end of midship shaft.

Done.

Made a bracket and mounted it in there, not Ideal by the book but this 1410 stuff is huge compared to the toyota shafts I am used to.

Kid ninjaed a pic while I was welding out passenger header.

Ran out of argon with half the collector to go.

Hadley added grab handles and steering wheel hanger.

Also built a mount for the overflow tank.

We quit early today to do some suspension tuning on the rzr.

[/URL

[/URL